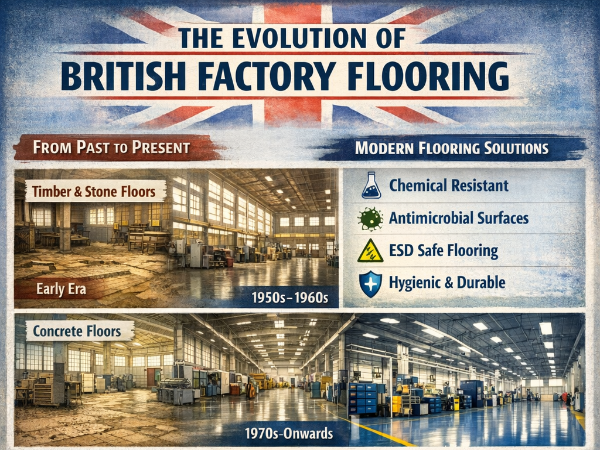

The Evolution of Factory Flooring Standards Across British Manufacturing

British factory floors have experienced remarkable changes over the past century. From the concrete slabs of early manufacturing plants to today’s sophisticated surfaces, industrial flooring has changed to meet increasingly demanding operational requirements. This progression reflects broader shifts in manufacturing standards, safety regulations, and production efficiency across the UK.

Specialised resin surfaces represent one of the most important advances in this field. These innovative materials appeared as manufacturers sought solutions that could withstand heavy machinery, chemical exposure, and constant foot traffic while maintaining safety standards. The development of robust flooring systems has paralleled the modernisation of British manufacturing facilities since the post-war industrial boom.

The Historical Development of British Factory Flooring

Documents from the industrial revolution note that timber and stone dominated early factory flooring. Timber allowed for quick repairs, while stone offered durability. Both materials had clear drawbacks in industrial settings.

Timber absorbed moisture and chemicals, creating safety hazards. Stone, while lasting longer, often became cold and uneven. By the 1950s, concrete became a common solution for factory floors across Britain.

Its hard-wearing nature and low cost suited factories needing durability. Still, uncoated concrete created dust, lacked chemical resistance, and was difficult to clean properly.

By the 1970s, resin technology began to appear in British factories, offering chemical-resistant coatings over concrete. Around this time, there was a growing emphasis on improving worker safety in industrial environments.

Industrial resin flooring met the demand for surfaces that performed under extreme stress. These solutions built on concrete’s strength but added surfaces able to withstand chemicals and heavy industrial work.

Modern Safety Requirements for Manufacturing Floors

Current UK guidelines focus on accident prevention, especially slip hazards. These continue to be a significant concern in industrial settings.

Various organisations provide resources for improving safety standards. Slip resistance is measured with the Pendulum Test Value (PTV), which is used to assess performance in wet and dry conditions.

Site managers test PTVs so that flooring in high-risk areas stays within safety limits. The minimum PTV follows a risk assessment that considers spill likelihood and traffic routes.

Chemical resistance requirements vary depending on the sector. Food plants need floors tough enough for disinfectants and organic acids. Pharmaceutical environments require surfaces that resist cleaning agents.

Slip Resistance Testing and Certification

UK slip resistance testing uses the pendulum device to measure friction and produce a PTV score. Recommendations for PTV levels may vary depending on the work environment and its specific needs.

Factories can find guidance through slip testing guides. R-ratings on technical datasheets range from R9 to R13, marking slip resistance levels for flooring materials.

Buyers should use technical documentation to select the best fit. With proper paperwork and regular testing, manufacturers show compliance with health and safety rules.

Technological Advancements in Factory Flooring Materials

Recent innovations have shaped factory settings. Modern systems include polyurethane and methyl methacrylate (MMA) formulations. Polyurethane offers flexibility and impact protection.

MMA resins allow for fast installation and curing, reducing downtime. Food and pharmaceutical sectors use resin floors with antimicrobial additives to help maintain hygiene standards.

These additives are designed to support standards such as HACCP for food and GMP for pharmaceuticals. Different sectors have varying requirements for these features.

Electronics facilities install electrostatic discharge (ESD) floors to protect sensitive equipment. These floors remove static electricity that could damage components.

Sector-Specific Flooring Solutions

Manufacturing sectors select flooring based on their unique conditions. Food factories use non-porous surfaces that are intended to comply with HACCP standards and help limit bacteria growth.

Facilities with constant movement choose options designed for temperature changes. Car assembly floors need strength to resist oil, fuel, and mechanical wear.

Electronics production benefits from systems with controlled static properties. Pharmaceutical operations need antimicrobial protection for cleanroom safety.

Cost-Benefit Analysis of Modern Factory Flooring

While installing advanced resin flooring brings higher up-front costs than older alternatives, the long-term results are often considered more cost-effective. A significant portion of flooring expenses can come from maintenance and replacement.

This reality changes how manufacturers approach flooring investments. Modern flooring is designed to reduce accident risks and improve staff wellbeing. Slip-resistant floors in packaging plants have reportedly helped reduce accidents.

Ergonomic surfaces improve comfort during long shifts and may help lower fatigue. For continuous production, limiting shutdowns is very important. Many resin options install during planned stoppages.

Quick-curing products allow factories to resume work in hours rather than days. Industrial resin flooring helps factories stay cleaner, safer, and more efficient.

Future Trends in British Manufacturing Flooring

Factory flooring is moving towards smart solutions with monitoring functions. Sensors embedded in floors can track temperature, pressure, or wear, giving early warnings before failures occur.

These features support Industry 4.0 practices, letting teams use floor data in their decision-making. Sustainability continues to drive new product development.

Manufacturers now request flooring with bio-based resins and recycled content. This trend fits with broader corporate environmental goals across British industry.

The integration of flooring systems with other factory technologies represents another important advance. Connected systems allow for better coordination between maintenance schedules.

As manufacturing processes continue to change, flooring requirements will likely become more specialised. This shift in perspective supports ongoing innovation in the sector.