Relay Tester: The Ultimate Guide to Testing and Maintaining Relays

Comprehensive Insights, Techniques, and Best Practices for Reliable Relay Performance

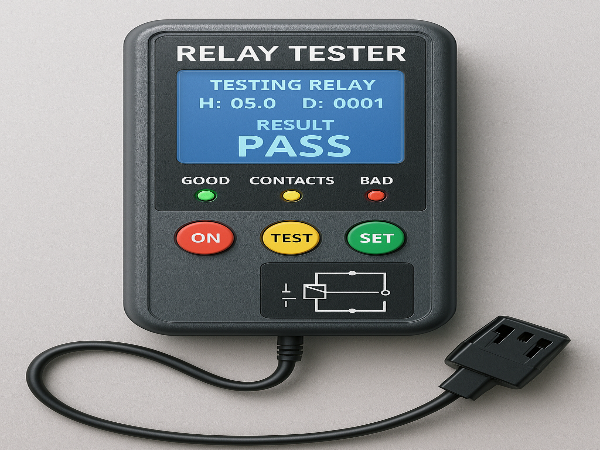

A Relay Tester is an essential diagnostic tool used to assess the performance, timing, and integrity of electrical relays across automotive, industrial, and power protection systems. By simulating real-world operating conditions, a relay tester identifies hidden faults such as contact wear, coil deterioration, timing delays, and insulation failures that a visual inspection cannot detect. Regular testing ensures equipment safety, prevents costly downtime, and extends the life of critical systems by detecting issues before they escalate into major failures.

Introduction

Relays are the silent workhorses of electrical and electronic systems, controlling circuits, protecting equipment, and ensuring smooth automation processes. Despite their compact size, relays play a pivotal role in maintaining operational safety and efficiency. However, their reliability can diminish over time due to contact wear, coil degradation, or environmental factors. This is where the Relay Tester becomes invaluable. By accurately measuring relay response, performance, and durability, relay testers help engineers, technicians, and maintenance professionals maintain system integrity and prevent unexpected failures.

What Is a Relay Tester?

A relay tester is a specialized instrument designed to evaluate the functionality of electrical relays under controlled conditions. Unlike basic visual inspections, which only reveal obvious defects, a relay tester simulates actual working environments, allowing technicians to observe how a relay responds to voltage, current, and timing parameters. Whether in automotive workshops, industrial plants, or power generation facilities, relay testers are indispensable for ensuring that relays operate as intended.

Key Functions of a Relay Tester

Performance Verification: Confirms that relays activate and release within specified voltage and current ranges.

Timing Analysis: Measures the delay between coil energization and contact movement, essential for protective and control systems.

Contact Resistance Testing: Evaluates the resistance across relay contacts to identify wear or corrosion.

Insulation Resistance Measurement: Detects leakage currents and potential dielectric breakdowns.

Fault Simulation: Allows technicians to mimic overloads or faults to test relay stability.

Importance of Using a Relay Tester

Testing relays with a dedicated instrument provides insights far beyond what can be achieved by sight or sound alone. The consequences of undetected relay faults can include equipment malfunction, system downtime, and even safety hazards. By regularly using a relay tester, organizations can:

Prevent Equipment Damage: Early detection of contact pitting, coil shorts, or timing issues helps avoid costly repairs.

Enhance Safety: Relays in protective circuits must function flawlessly to prevent fires, shocks, or overloads.

Minimize Downtime: Scheduled testing reduces unexpected interruptions, keeping operations smooth.

Optimize Maintenance Costs: Proactive testing is more cost-effective than emergency repairs or replacements.

Types of Relay Testers

Relay testers come in various forms, each tailored to specific applications and testing complexity. Understanding these types helps users select the right tool for their needs.

Automotive Relay Testers

Designed for 12V and 24V systems, automotive relay testers are compact and user-friendly. They test common relays found in vehicles, such as those controlling headlights, fuel pumps, and cooling fans.

Universal Bench Relay Testers

These versatile units accommodate a range of relay types and voltages. They are ideal for laboratories, repair shops, and quality control environments.

Protection Relay Test Sets

Used in power generation, substations, and industrial plants, protection relay test sets simulate complex electrical conditions. They measure timing, fault response, and stability in protective relays that safeguard high-voltage systems.

Portable Relay Testers

Lightweight and battery-powered, portable relay testers are perfect for fieldwork. They offer convenience without sacrificing accuracy.

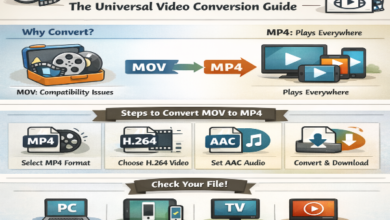

How to Use a Relay Tester Effectively

Proper use of a relay tester maximizes its benefits and ensures accurate results. Here’s a step-by-step guide:

Identify Relay Pins: Locate coil terminals, normally open (NO), normally closed (NC), and common contacts.

Set the Appropriate Parameters: Select the correct voltage, current, and test mode based on the relay specifications.

Connect the Relay Securely: Ensure firm connections to prevent erroneous readings.

Apply Test Signals: Energize the coil while observing contact switching and timing.

Record Measurements: Note pick-up voltage, release voltage, contact resistance, and actuation time.

Analyze Results: Compare the readings to manufacturer standards to confirm relay health.

Simulate Fault Conditions (if applicable): For protective relays, introduce overloads or short circuits to check response.

Common Faults Detected by a Relay Tester

A relay tester helps reveal issues invisible to the naked eye, such as:

Contact Pitting or Corrosion: Increases resistance and reduces conductivity.

Coil Short Circuits or Opens: Affects relay actuation and stability.

Delayed or Sticking Contacts: Causes timing errors in control systems.

Insulation Breakdown: Leads to leakage currents and potential hazards.

Incorrect Pick-Up or Drop-Out Voltage: Indicates mechanical or electrical wear.

Best Practices for Relay Testing

To achieve consistent and reliable results, follow these best practices:

Regular Testing Schedule: Implement periodic testing aligned with system criticality.

Calibrate Test Equipment: Ensure your relay tester is calibrated for precise readings.

Document Test Results: Maintain logs to track relay performance trends.

Test Under Realistic Conditions: Simulate load or fault scenarios to evaluate relay response.

Train Personnel: Ensure technicians understand relay operation and testing techniques.

Safety Precautions During Relay Testing

Working with electrical components requires strict safety measures:

Always de-energize circuits before connecting a relay tester.

Wear appropriate personal protective equipment (PPE).

Verify voltage ratings before testing to avoid overloading the relay.

Follow manufacturer instructions for both the relay and the tester.

Keep the work area organized and free of conductive debris.

Benefits of Investing in a Quality Relay Tester

Purchasing a reliable relay tester is a long-term investment that offers multiple advantages:

Enhanced Reliability: Early fault detection keeps systems operating optimally.

Extended Equipment Lifespan: Regular testing prevents cumulative damage.

Cost Savings: Preventive maintenance reduces emergency repair costs.

Operational Efficiency: Testing ensures relays perform as designed, supporting overall productivity.

Improved Compliance: Many industries require documented relay testing to meet safety and performance standards.

Choosing the Right Relay Tester

Selecting an appropriate relay tester depends on your specific application:

For Automotive Work: Look for portable testers with simple interfaces and compatibility with 12V/24V relays.

For Industrial Maintenance: Choose a bench tester that supports multiple relay types and has advanced measurement features.

For Power Protection Systems: Opt for a protection relay test set with multi-phase capability, fault simulation, and precise timing analysis.

For Field Applications: A rugged, battery-operated model ensures flexibility and durability.

Evaluate factors such as testing range, ease of use, portability, and available accessories before making a decision.

Maintenance and Calibration of Relay Testers

To maintain accuracy and longevity, relay testers themselves require proper care:

Regular Calibration: Schedule periodic calibration according to manufacturer recommendations.

Cleanliness: Keep terminals and connectors free from dust and oxidation.

Battery Care (for portable models): Charge and store batteries properly to extend their life.

Firmware Updates: If your tester includes software, keep it updated for the latest features and performance improvements.

The Future of Relay Testing

Advances in technology are making relay testing more efficient and intelligent:

Automated Test Sequences: Reduce human error and save time.

Digital Interfaces: Enable seamless data transfer and analysis.

Remote Monitoring: Allows technicians to test and evaluate relays from a distance.

AI and Predictive Analytics: Emerging tools can predict relay failures based on historical data.

These innovations will enhance reliability and streamline testing workflows across industries.

Conclusion

A Relay Tester is more than just a diagnostic tool; it is a safeguard for the electrical systems that power our world. By detecting faults invisible to the naked eye and providing precise measurements of relay performance, it plays a vital role in ensuring safety, reliability, and efficiency. Whether in automotive repair, industrial maintenance, or high-voltage protection, investing in the right relay tester and adopting best testing practices will protect your equipment, save costs, and support uninterrupted operations.